digital fabrication

exercises

These three exercises severed as an introduction into N.U.R.B.S. modeling and focused on the transition from digitally generated designs into the constructed physical.

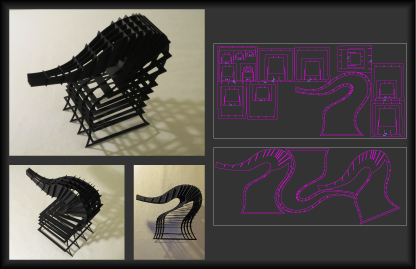

contouring exercise - laser cutting

The first of the three projects, this exercise utilizes a method of representing digital volumes physically know as contouring. Also known as sectioning, this approach converts the digital forms into planer, commonly parallel, sheets that can be fabricated through CAM techniques such as laser cutting or milling. The unique digital geometry, an older ceramic project, was chosen due to the innovation required to fabricate the piece through this technique.

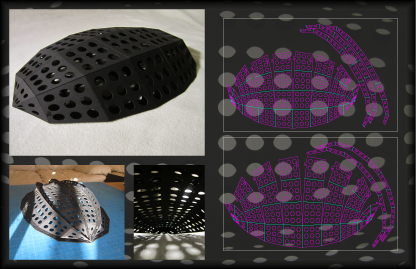

tessellating exercise - laser cutting

The second exercise was executed using another CAD translation method referred to as tessellating. In this process, digital volumes maintain their overall geometry and dimensions, but are broken down into repeating two-dimensional planes. Additionally, this project used a process known as paneling to map geometries onto the tessellated surfaces.

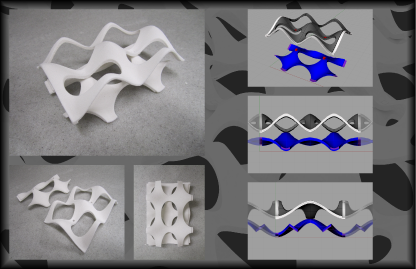

forming & casting exercise - 3d printing

The final exercise employs full volumetric representation of a digital model through additive 3d printing. The piece is constructed of two parts and is then to be molded and cast out of hydrocal. Multiple casts are then made of the design which allows for the cast to be connected horizontally, creating a light screen plane. Tolerances are precisely calculated due to the increased chance of imperfections and the addition of an adhesive material.